Professional Corundum Gemstones Supplier – Chromium Corundum Refractory Products – Wanyu

Professional Corundum Gemstones Supplier – Chromium Corundum Refractory Products – Wanyu Detail:

product description

The raw material used in the chromium corundum series products is a solid solution synthesized by high-temperature melting of alumina and chromium oxide in a certain proportion. The main raw material is high bauxite (or industrial alumina) by adding appropriate amount of chromite and reducing it. The agent is melted at a high temperature in an electric furnace, and the molten chromium is poured into the mold to be slowly cooled, and then it is made after annealing. .

Chromium corundum refractory products fused cast chrnmecorundum refrac-tory is also called fused cast chrnmecorundum refrac-tory. A fused cast refractory product composed of a solid solution of alumina and chromium oxide and a small amount of spinel, which contains 60% to 87% of alumina and 30% of chromium oxide. The bulk density is 3.2-3.9g/cm3;, the high temperature strength is higher, compared with other types of corundum refractories, the corrosion resistance of glass melt is the strongest. It can be used as the lining of the kiln that is in direct contact with the molten glass.

Chromium corundum refractories are widely used in the lining of coal-water slurry pressurized gasifier, ladle refining furnace and carbon black reactor lining, petrochemical industry slag gasification furnace lining and glass melting furnace lining, etc., and can also be used for heating The chrome corundum platform brick for furnace is an indispensable material in high temperature industry.

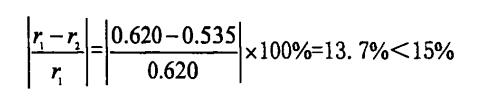

AL203 and Cr2O3 belong to the corundum structure, the radius of Cr3+ is 0.620, and the radius of AL3+ is 0.535. According to the empirical formula:

Since the difference between Cr3+ and AL3+ ion radii is less than 15%, Cr ions can continuously and infinitely replace AL in the AL203 lattice, forming an infinite continuous replacement solid solution.

The crystal structure of Cr203 and AL203 are the same, and the ionic radius differs by 13.7%. Therefore, Cr203 and AL203 can form an infinite solid solution at high temperature. From the perspective of the liquid-solid phase line, with the increase of Cr203 content, the temperature at which the liquid phase begins to appear also rises. Therefore, adding an appropriate amount of Cr203 to AL203 can significantly improve the mechanical properties and high-temperature service performance of corundum refractories

Cr203 can form a high melting point compound or a eutectic with a higher melting temperature with many common oxides. For example, FeO·Cr203 spinel produced by Cr203 and Feo has a melting point as high as 2100℃; Cr203 and AL203 can form a continuous solid solution. In addition, Cr203 can also greatly increase the viscosity of the slag and reduce the fluidity of the slag, thereby reducing the corrosion of the slag to the refractory. Therefore, adding an appropriate amount of Cr203 to the refractory material can significantly reduce the structural spalling of the furnace lining material caused by slag erosion. There is no obvious regularity between the corrosion ability of slag to chromium corundum refractories and the basicity of slag.

The chromium corundum brick made of chromium corundum refractory material is in the furnace. When the slag basicity is 2, the chromium corundum brick has the best resistance to iron slag corrosion; when the slag basicity is 0.2, the corrosion depth of the copper slag to the chromium corundum brick The smallest; when the slag basicity is 0.35, the corrosion depth of tin slag to the chrome corundum brick is the smallest; when the lead slag basicity is 0.3, the thickness of the residue is the largest and the depth of the reaction layer, the erosion layer and the penetration layer is the smallest. When the slag alkalinity is 0.37, the corrosion resistance of chrome corundum bricks is the best.

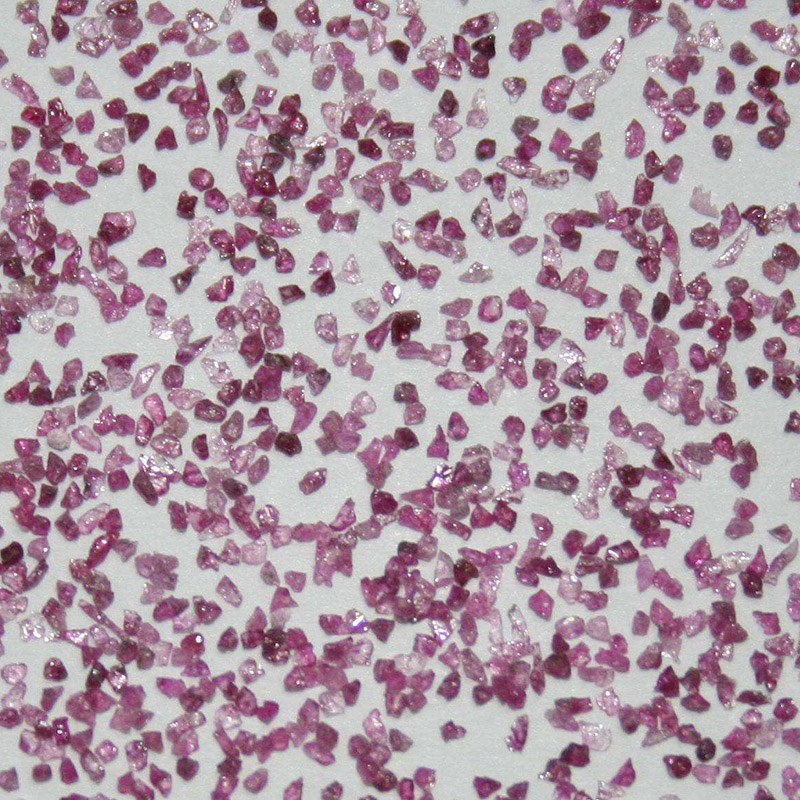

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for Professional Corundum Gemstones Supplier – Chromium Corundum Refractory Products – Wanyu , The product will supply to all over the world, such as: Algeria, Czech Republic, Bulgaria, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!