1、 What is refractory?

Refractory materials generally refer to inorganic non-metallic materials with a fire resistance of more than 1580 ℃. It includes natural ores and various products made through certain processes according to certain purpose requirements. It has certain high-temperature mechanical properties and good volume stability. It is a necessary material for all kinds of high-temperature equipment. It has a wide range of uses.

2、 Types of refractories

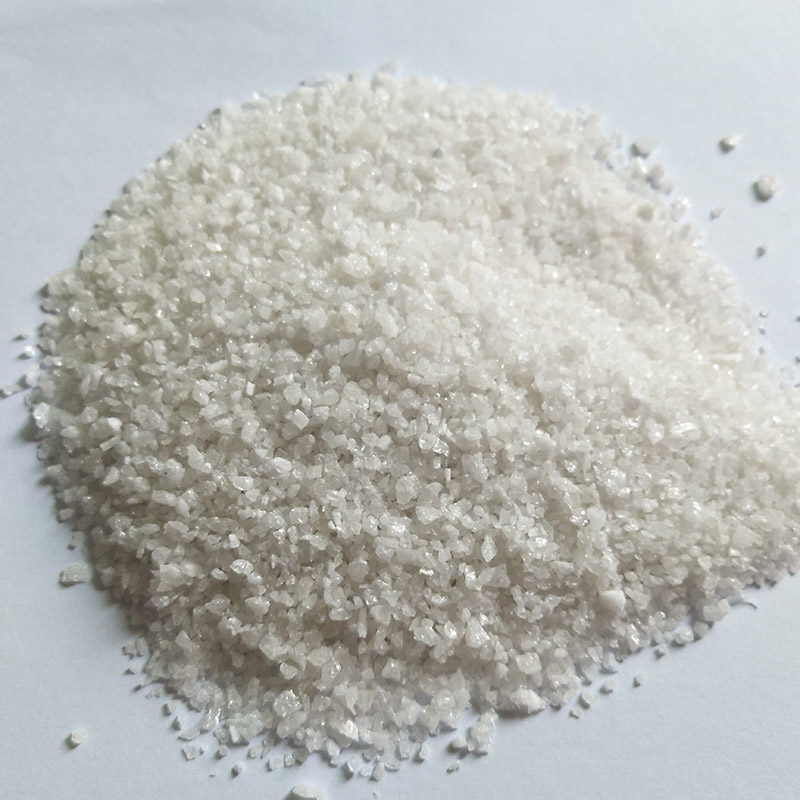

1. Acid refractories usually refer to refractories with SiO2 content greater than 93%. Its main feature is that it can resist the erosion of acid slag at high temperature, but it is easy to react with alkaline slag. Silica bricks and clay bricks are commonly used as acid refractories. Silica brick is a siliceous product containing more than 93% silicon oxide. The raw materials used include silica and waste silica brick. It has strong resistance to acid slag erosion, high load softening temperature, and does not shrink or even expand slightly after repeated calcination; However, it is easy to be eroded by alkaline slag and has poor thermal vibration resistance. Silica brick is mainly used in coke oven, glass furnace, acid steel furnace and other thermal equipment. Clay brick takes refractory clay as the main raw material and contains 30% ~ 46% alumina. It is a weakly acidic refractory with good thermal vibration resistance and corrosion resistance to acidic slag. It is widely used.

2. Alkaline refractories generally refer to refractories with magnesium oxide or magnesium oxide and calcium oxide as the main components. These refractories have high refractoriness and strong resistance to alkaline slag. For example, magnesia brick, magnesia chrome brick, chrome magnesia brick, magnesia aluminum brick, dolomite brick, forsterite brick, etc. It is mainly used in alkaline steel-making furnace, non-ferrous metal smelting furnace and cement kiln.

3. Aluminum silicate refractories refer to refractories with SiO2-Al2O3 as the main component. According to the Al2O3 content, they can be divided into semi siliceous (Al2O3 15 ~ 30%), clayey (Al2O3 30 ~ 48%) and high alumina (Al2O3 greater than 48%).

4. Melting and casting refractory refers to the refractory products with a certain shape cast after melting the batch at high temperature by a certain method.

5. Neutral refractories refer to refractories that are not easy to react with acidic or alkaline slag at high temperature, such as carbon refractories and chromium refractories. Some also attribute high alumina refractories to this category.

6. Special refractories are new inorganic nonmetallic materials developed on the basis of traditional ceramics and general refractories.

7. Amorphous refractory is a mixture composed of refractory aggregate, powder, binder or other admixtures in a certain proportion, which can be used directly or after appropriate liquid preparation. Unshaped refractory is a new type of refractory without calcination, and its fire resistance is not less than 1580 ℃.

3、 What are the frequently used refractories?

Common refractories commonly used include silica brick, semi silica brick, clay brick, high alumina brick, magnesia brick, etc.

Special materials often used include AZS brick, corundum brick, directly bonded magnesium chromium brick, silicon carbide brick, silicon nitride bonded silicon carbide brick, nitride, silicide, sulfide, boride, carbide and other non oxide refractories; Calcium oxide, chromium oxide, alumina, magnesium oxide, beryllium oxide and other refractory materials.

The frequently used thermal insulation and refractory materials include diatomite products, asbestos products, thermal insulation board, etc.

The frequently used amorphous refractory materials include furnace mending materials, fire-resistant ramming materials, fire-resistant castables, fire-resistant plastics, fire-resistant mud, fire-resistant gunning materials, fire-resistant projectiles, fire-resistant coatings, light fire-resistant castables, gun mud, ceramic valves, etc.

4、 What are the physical properties of refractories?

The physical properties of refractories include structural properties, thermal properties, mechanical properties, service properties and operational properties.

The structural properties of refractories include porosity, bulk density, water absorption, air permeability, pore size distribution, etc.

The thermal properties of refractories include thermal conductivity, thermal expansion coefficient, specific heat, heat capacity, thermal conductivity, thermal emissivity, etc.

The mechanical properties of refractories include compressive strength, tensile strength, flexural strength, torsional strength, shear strength, impact strength, wear resistance, creep, bond strength, elastic modulus, etc.

The service performance of refractories includes fire resistance, load softening temperature, reheating line change, thermal shock resistance, slag resistance, acid resistance, alkali resistance, hydration resistance, CO erosion resistance, conductivity, oxidation resistance, etc.

The workability of refractory materials includes consistency, slump, fluidity, plasticity, cohesiveness, resilience, coagulability, hardenability, etc.

Post time: Mar-15-2022