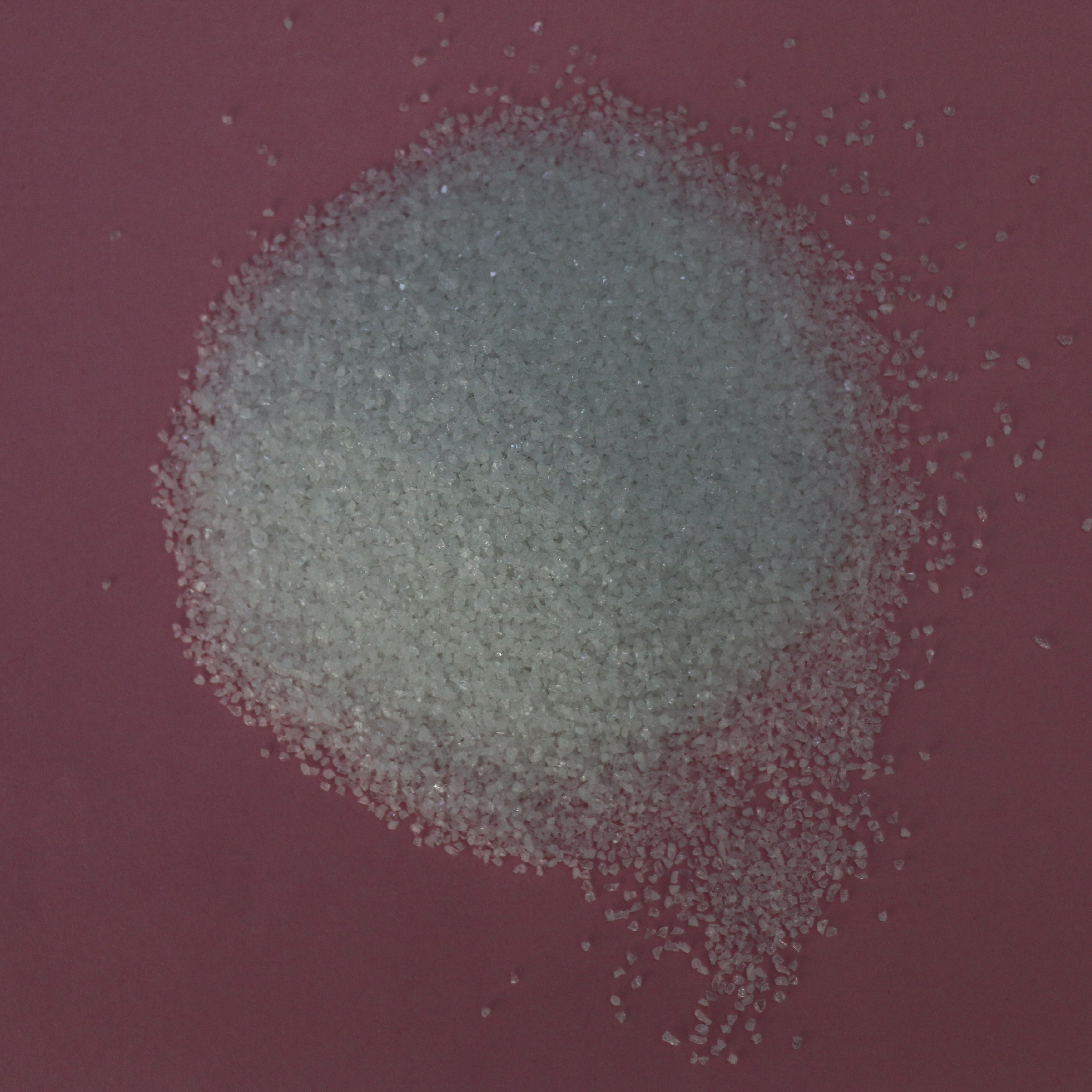

The shape of the superabrasive particles and the composition of the coating play an important role in the suitability of grinding wheels for various applications.

Matching the application to the optimal superabrasive wheel can benefit by improving part quality and product yield, making in-depth knowledge of grit, bond and coating properties critical for grinder users. Photo courtesy of Wanyu Abrasives.

The right choice of super hard grinding wheels is essential for an efficient grinding process. The right wheel can optimize parts per hour, reduce tool changes, increase machine uptime, improve product quality and reduce operating costs. However, finding such a wheel requires careful study of the grain shape and superabrasive coating, among other characteristics.

Superabrasive grinding wheels operate under severe grinding conditions and must have a number of properties, including hardness at high temperatures, high thermal conductivity to remove heat from the cutting edge, compositional stability, wear resistance, lubricity and resistance to plastic deformation.

The performance of a superabrasive grinding wheel is primarily determined by the bonded substrate, as well as the inherent characteristics and quality of the abrasive grain of the wheel, be it diamond or cubic boron nitride (CBN). Different particles and coatings provide different strengths and are therefore suitable for different applications. Knowing which particles and coatings are best for specific applications can save manufacturers money over time.

Depending on the application or grinding process, premium grain or more expensive grain may be the most economical option for the job. Likewise, the most expensive diamond or CBN wheels may not be suitable for a given application. What matters is not the price, but the shape of the superabrasive grains and the type of coating used on the wheel.

Toughness refers to the behavior of an abrasive grain under mechanical stress, that is, its ability to resist cracking, chipping, and breaking. Brittleness refers to the ability of the grain to break and self-sharpen.

Harder super abrasive grains tend to be clumpy and hold their shape better than they remove material. Brittle particles are periodically sharpened, their angular shape removes more material with each pass. Different applications require grains at different points on the spectrum between these two forms.

In terms of form, there are two polar categories: blocky and angular. The more agglomerated or rounded the abrasive particles, the less effective the cutting, but the better the shape is retained. Clumped particles are stronger and withstand higher abrasive forces before breaking.

Conversely, angular shapes are more aggressive and better penetrate and remove material. However, angular grains are destroyed with less effort.

Ideally, there should be a particle that balances these two shapes, allowing it to remain rigid, allowing it to naturally break down, revealing a new, sharp cutting edge. Without the ability to disintegrate, the grains will dull and rub against the workpiece instead of cutting, causing a surge in grinding force and serious problems for the wheel and workpiece.

Coating is the process of completely and uniformly coating superabrasive grains with a layer of additional material. This process increases grain size and weight, which is often used to improve qualities such as strength and durability in grinding.

The strength of the bonded matrix to hold the abrasive grain determines the effectiveness of the grinding wheel. The main advantage of the coatings is that they can texture the diamond or CBN particles to better adhere to the wheel, be it resin, vitreous, metal, hybrid or other. Improved mechanical and chemical retention of the bonding system enhances wheel integrity.

The cost savings and maximum productivity that come with choosing the right grinding wheel can easily become a competitive advantage if the workshop plays its cards right.

Nickel, copper and silver coatings are the most common superabrasive coatings. Nickel plating is common in resin bonded wheels. These coatings improve wheel life, surface finish, heat dissipation and mechanical adhesion to bonding surfaces to maximize performance.

Copper coatings are the coating of choice for dry grinding due to the ability of copper to conduct heat away from the grinding area and improve the retention of mechanical and chemical particles in the bonded system.

Silver coatings are more expensive but offer the highest thermal conductivity of the three coating types, as well as improved particle retention and additional lubricity. Silver is the preferred finish when pure oil is used as the coolant.

The amount of coating on the abrasive grain can be from 30% to 70% of the total weight of the coated grain. Coatings on diamond particles are typically 50% to 56% by weight, while CBN particles are often used for coatings at 60% by weight. Coated superabrasives tend to be more expensive than uncoated abrasives due to their higher expected performance and the additional manufacturing steps required to produce them.

Even minor adjustments to the abrasive in the grinding wheel can be a game changer for your grinding system and process. Cost savings and productivity gains from choosing the right grinding wheel can easily become a competitive advantage if the workshop plays its cards right.

By using advanced, high-performance milling techniques in the machining program, SolidCAM iMachining technology can significantly reduce cycle times and significantly increase tool life compared to traditional milling.

The forces involved in the milling process can be quantified, allowing mathematical tools to be used to predict and control these forces. Precise formulas for calculating these forces allow you to optimize the quality of milling work.

Post time: Apr-23-2023