Good Refractory Corundum Manufacturers – Pink corundum tip crystal chrome corundum section abrasive polishing – Wanyu

Good Refractory Corundum Manufacturers – Pink corundum tip crystal chrome corundum section abrasive polishing – Wanyu Detail:

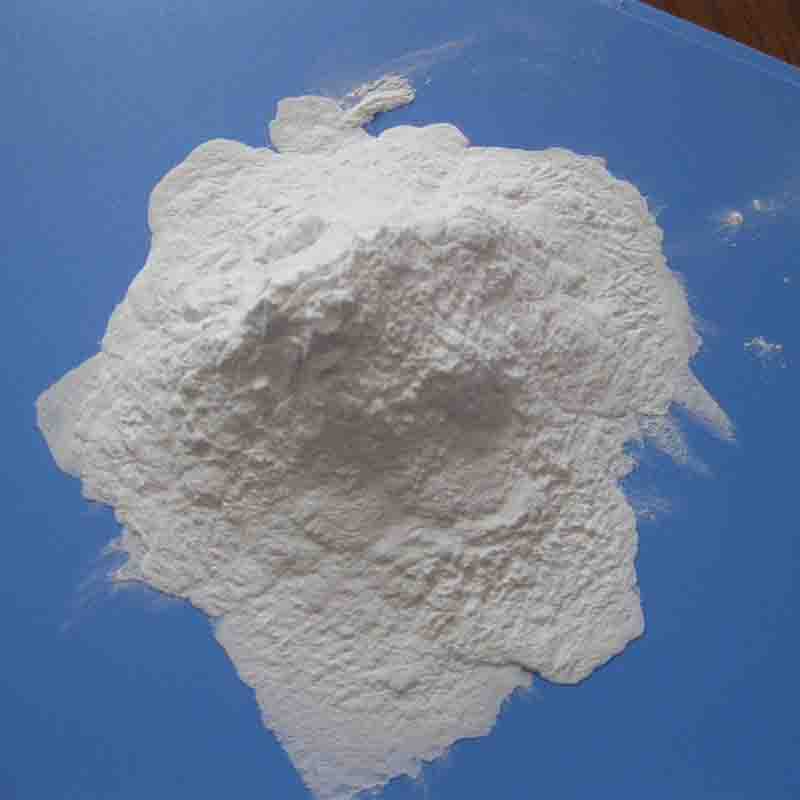

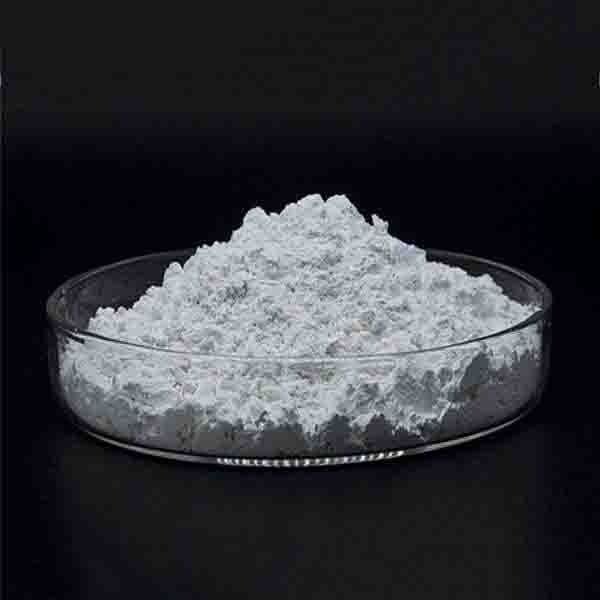

Chromium corundum is made of alumina powder as the main raw material, suitable for chromium oxide, etc., after high temperature smelting. It is pink, the hardness is similar to that of white corundum, and the toughness is higher than that of white corundum. The abrasive tools manufactured by it have good durability and high finishing finish. It is suitable for precision grinding of measuring tools, instrument parts, threaded workpieces and template grinding. So what are the production processes and uses of chromium corundum?

Production process of chromium corundum

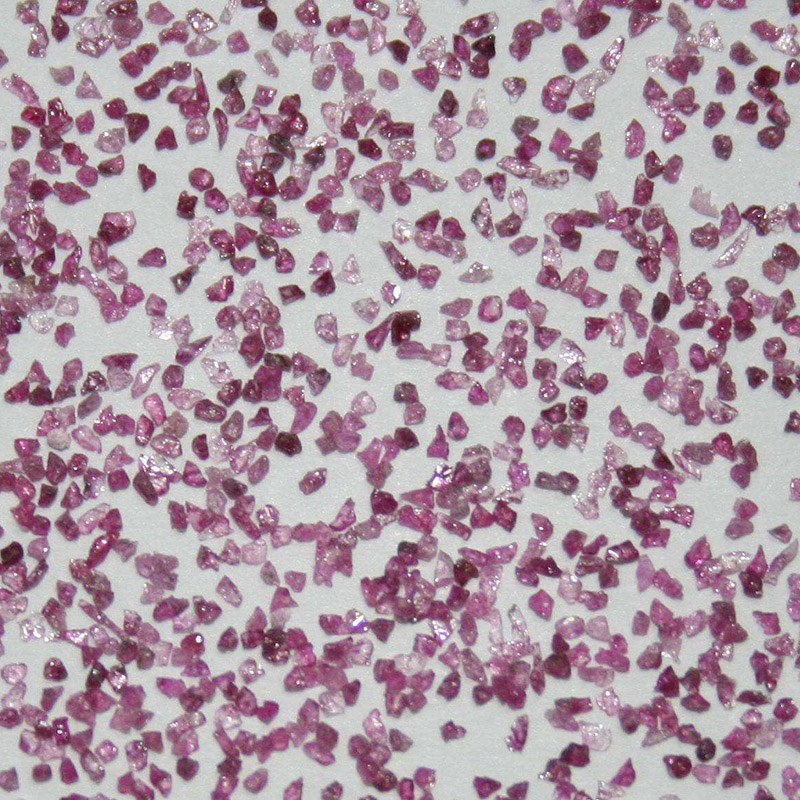

The smelting process of chromium corundum is the same as that of white corundum, except that a certain amount of chromium oxide is added during the smelting process, which is light purple or rose. Since the introduction of Cr3+ in chromium corundum improves the toughness of the abrasive, its toughness is higher than that of white corundum, and its hardness is similar to that of white corundum. When used for processing tougher materials, its processing efficiency is higher than that of white corundum, and the surface finish of the workpiece is also Better, chromium corundum is suitable for processing high toughness hardened steel, alloy steel, precision measuring tools and instrument parts and other workpieces with high finish requirements.

The use of chromium corundum abrasive

Chrome corundum has the characteristics of pink color, high hardness, high toughness, high purity, excellent self-sharpening, strong grinding power, low heat generation, high efficiency, acid and alkali corrosion resistance, high temperature resistance, and good thermal stability.

Ideal sandblasting, suitable for sandblasting of hardware, glass, zinc alloy, aluminum alloy, stainless steel, high carbon steel, high speed steel, etc. In particular, the effect of spraying thin-walled workpieces is obvious, the workpiece does not change color, and the processing finish is high.

It can improve the smoothness of silicon wafers, optical lenses, precision instruments, polished glass bulbs, glassware, ceramic stones, leather, plastics, and metal parts.

The abrasive tools made of it have sharp grinding, low heat generation rate, high grinding ratio, and little adhesion during use; the sintered abrasive tools made have a dark blue color after firing, no mesh cracks, and no rust spots. Features.

Abrasives made of chromium corundum have good durability and high finish. It is suitable for precision grinding of measuring tools, machine tool spindles, instrument parts, threaded workpieces and model grinding.

Chromium corundum is suitable for manufacturing ceramics and resin high-consolidation abrasive tools, as well as grinding and polishing.

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Good Refractory Corundum Manufacturers – Pink corundum tip crystal chrome corundum section abrasive polishing – Wanyu , The product will supply to all over the world, such as: US, Slovakia, Colombia, Insisting over the high-quality generation line management and prospects guide provider, we've made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.