Alumina Bricks Manufacturers – High temperature calcined α alumina powder – Wanyu

Alumina Bricks Manufacturers – High temperature calcined α alumina powder – Wanyu Detail:

feature of product

High-temperature calcined alumina powder products have a higher melting point, excellent mechanical strength, hardness, high electrical resistivity and thermal conductivity. Can be widely used in industries such as electronic equipment, structural ceramics, refractory materials, wear-resistant materials, polishing materials, etc.

product category

According to different physical and chemical indexes, high-temperature calcined alumina powder products are mainly divided into boron-fluorine (BF2:1), boron-fluorine (BF5:1), pure fluorine (F), pure boron (B), and non-mineralized according to the formula of mineralizer. There are five types of agents, and special alumina such as Boron Chlorine (BL) and Fluorine Chlorine (FL); Alumina powder products are divided into 325 mesh, 400 mesh, 500 mesh, 600 mesh, 800 mesh powder, and fine crystalline powder.

According to different application requirements, five series of products including dry pressing, isostatic pressing process series, hot die casting, grouting molding series, refractory series, casting molding series, and alumina structural ceramic granulation powder have been formed.

Dry pressing, isostatic pressing process series

This series of products are refined with advanced formula and strict technology, with reasonable particle size distribution, good particle fluidity, loose inter-grain bonding, good grindability, and easy sintering. Its porcelain pieces are compact, smooth surface, high mechanical strength, and good electrical insulation. It is an ideal raw material for manufacturing special ceramics.

Hot die casting, grouting molding series

This series of products have large primary crystal particle size, stable performance, good molding performance, small product shrinkage, and a wide range of applications. They are especially suitable for hot die casting and grouting molding series, and can be used for various high-temperature resistant ceramic parts (spark plugs, etc.) and resistant Grinding ceramic parts (mortar pump shaft plug pump lining, impeller, grinding media ball, etc.), electronic substrates, electronic vacuum tubes, etc.

Refractory series

The product has stable crystal form, can improve the refractoriness of the product, and improve the mechanical properties. It is suitable for the production of unshaped refractory materials (various high-aluminum castables), shaped refractories (corundum bricks, etc.), furnace building materials, etc., to meet customer comparisons High temperature, excellent thermal shock stability and processing characteristics are required to extend the service life of refractory materials.

Pouring stereotypes series

The product has uniform crystal grains, good filling performance and pouring activity, which can increase the sintered density, high temperature flexural and compressive strength of the castable, and enhance the wear-resistant, corrosion-resistant, and erosion-resistant properties of the castable. It can be used for low-cement, ultra-low-cement or non-cement castables, shaped refractories and precision polishing.

Alumina ceramic granulated powder

It is made by scientific research ingredients, automatic grinding, pulping and spray drying. The particle size distribution is uniform, the fluidity is good, and the strength is moderate; the produced body has high strength, excellent demoulding performance, and low firing temperature; the surface of the product is smooth and the structure is compact. It can meet the technological requirements for rapid dry pressing of precision ceramics, and is an ideal raw material for the production of electronic ceramics and structural ceramic components.

Application areas

1. Sealing ring, friction plate, vacuum tube, electronic substrate

2. Structural ceramics, electronic ceramics, bio-ceramics, advanced refractory materials

3. Ball mill lining, ceramic bearing, ceramic cutter

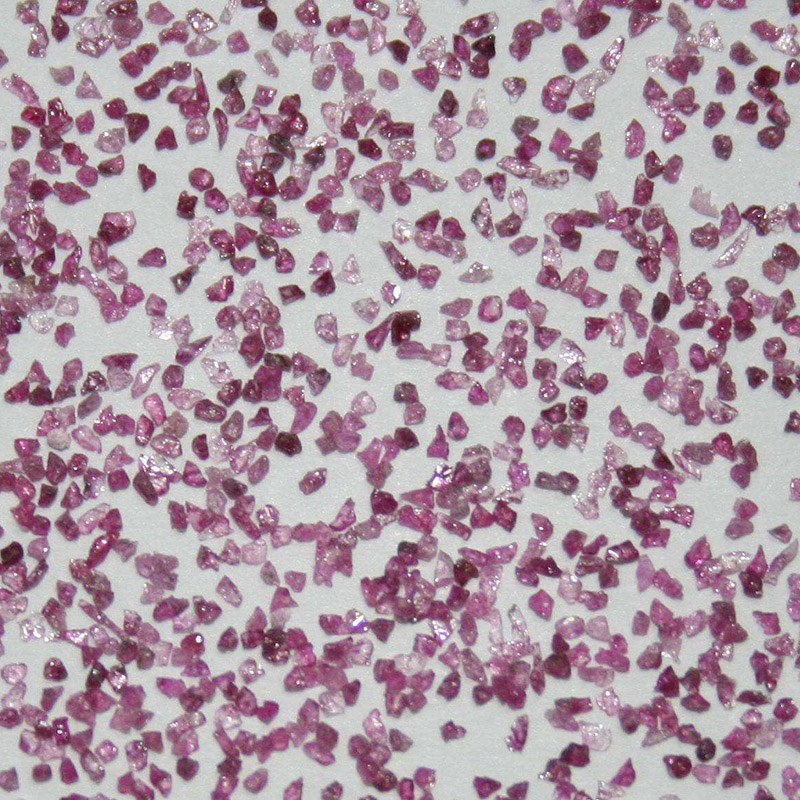

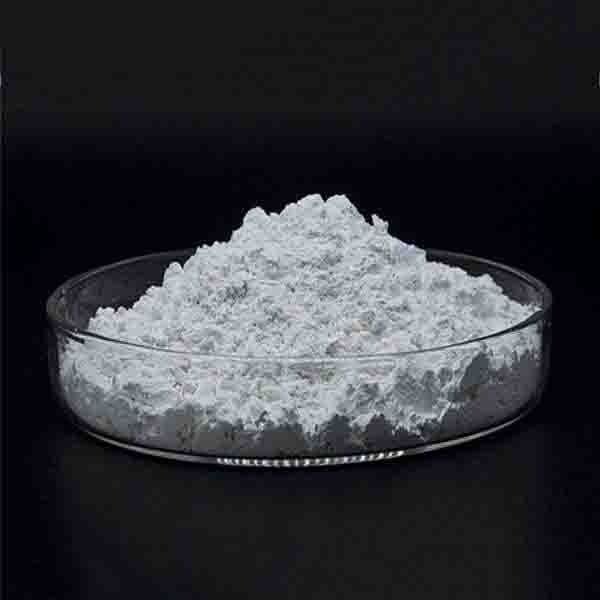

Product detail pictures:

Related Product Guide:

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for Alumina Bricks Manufacturers – High temperature calcined α alumina powder – Wanyu , The product will supply to all over the world, such as: South Korea, Philippines, Buenos Aires, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.